SINGLE WORMS GRINDERS:

MG 200

MG 330

MG 400

MG 400 Low

material, such as frozen blocks, from being ejected during feeding of the

grinder.

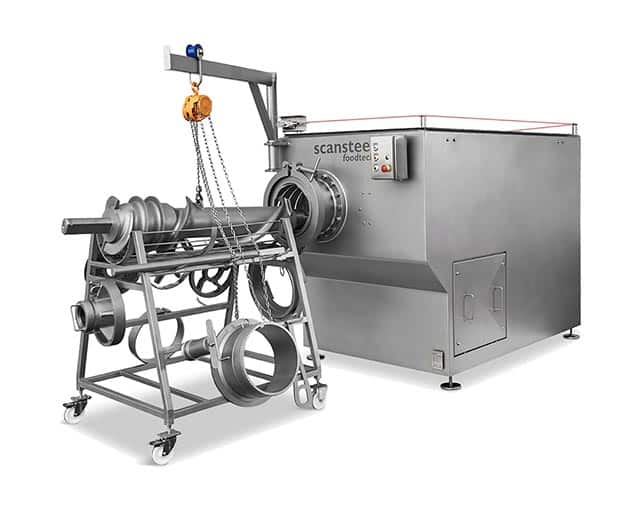

inspection. The automatic greasing system for main bearing and front bearing

is also shown.

inspection.

Cabinet without worm

showing the flights of

the lining.

400/260 shown

disassembled, with worm

in place, ready for

mounting of 3-bladed

cut-knife. Cutknife

recessed into worm.

400/260 shown with

worm and 3-bladed

cut-knife assembled.

with knife set and front

end fully assembled.

Automatic greasing of

front end bearing is shown

as well.

be coming soon..

Over the years, the scansteel foodtech A/S has conquered the position as THE supplier with the world’s widest grinder programme. scansteel foodtech A/S delivers, among other, the following single worm grinder programme:

scansteel foodtech grinders® are normally used for the following applications (but not limited hereto):

• Fresh meat raw material.

• Frozen blocks of meat raw material.

• Bones – beef, pork, poultry, fish, etc.

• Fat – all types and temperatures.

• Fish – all types.

• Fish offal.

• By-products

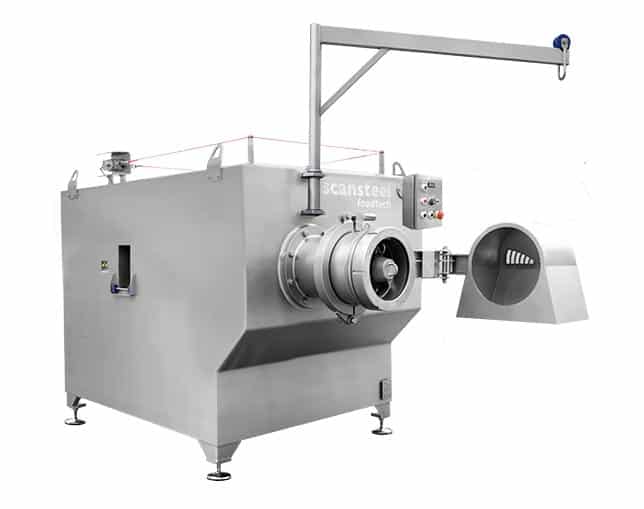

Cabinet Grinders (Type name: MG)

scansteel foodtech® Cabinet Grinders ranging from

Ø200 mm – Ø550 mm (Ø8” – Ø22”) – 22 kW – 200 kW

Open Cabinet Grinders (Type name: MG Low)

scansteel foodtech® Open Cabinet Grinders ranging from

Ø200 mm – Ø550 mm (Ø8” – Ø22”) – 22 kW – 200 kW

SINGLE WORM GRINDERS FEATURES:

• Constructed in stainless steel AISI 304.

• Grinders from Ø250 mm – Ø550 mm.

• Grinding capacities from 2000 – 40,000 kg/hour.

• Optional hydraulic knife tensioning system.

• Large hopper infeed area preventing bridge building.

• Low noise level.

• Low energy consumption.

• 75 kW – 200 kW motor.

• 1 or 2 units dismantling crane.

• Heavy Duty construction.